Southeast Region’s Pollution Prevention Recognition Program

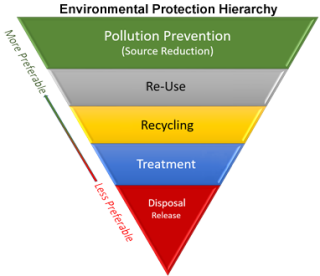

Pollution Prevention (P2) is any practice that reduces, eliminates, or prevents pollution at its source. EPA’s P2 Program is a non-regulatory approach to conserve energy and water, reduce the use of toxic materials, reduce harmful air emissions at the source, and save money.

The EPA P2 Recognition Program is an annual, voluntary, and non-monetary awards program that recognizes organizations whose P2 successes and practices exemplify environmental excellence and innovation.

Organizations that would like to be considered for P2 Recognition should complete the online application questionnaire during the open nomination period every year.

- Learn more about the definition of P2 and what EPA is doing.

- Learn about the 2024 R4 P2 Award winners

- Learn about the 2023 R4 P2 Award winner

- Learn about the 2021 R4 P2 Award winners

- Apply online for the 2024 P2 Recognition Program

- Visit EPA’s P2 Resources for Businesses to find P2 technical assistance providers in your area.

Who is Eligible?

Organizations—including both nonprofit and for-profit businesses and facilities—located within EPA Region 4 are eligible for a Region 4 P2 Recognition Program. EPA Region 4 includes Alabama, Florida, Georgia, Kentucky, Mississippi, North Carolina, South Carolina, Tennessee and six federally recognized Tribes. Governmental organizations, EPA P2 grant and cooperative agreement recipients, and EPA P2 contractors are not eligible for this award program. However, organizations assisted by Region 4 P2 grant recipients may apply.

P2 Recognition Program awards organizations that have implemented pollution prevention projects and/or process improvements at their facilities. Pollution prevention technologies on the market or pollution prevention consultant services are not eligible. EPA does not endorse the products, services, or enterprises of non-federal entities.

EPA will conduct a compliance screening for all eligible award applications.

You may be eligible for other EPA P2 awards, which include but are not limited to:

- Safer Choice Partner of the Year Awards

- Green Chemistry Challenge Awards

- If you are located outside of EPA Region 4, contact your Regional P2 Coordinator to determine if your Region offers a P2 Awards program.

What Projects Are Eligible?

Projects eligible for the awards must have taken place within the past three years within Region 4. Eligible projects must also meet the goals of the P2 program, which include but are not limited to:

- Eliminate or reduce greenhouse gas generation.

- Conserve natural resources and materials, including water and energy.

- Prevent spills and accidental releases to air, land, and water.

- Reduce hazardous materials use.

- Promote the purchasing and use of less hazardous or more efficient products and equipment.

- Implement green chemistry practices.

- Increase a business’s efficiency while increasing sustainable practices.

Examples of P2 activities or projects:

- Substituting hazardous chemicals with safer alternatives.

- Conserving water and/or energy.

- Equipment or technology modifications, process or procedure modifications, reformulation, or redesign of products.

- Reducing use of raw or virgin materials.

- Reducing chemical use.

Case studies and additional examples of P2 activities and projects can be found in EPA’s P2 Resources Search Tool.

Projects that are not eligible include recycling of discarded materials, waste cleanup or disposal activities, composting, processing non-hazardous solid waste (e.g., paper, aluminum, etc.), or activities that do not reduce the use or release of hazardous substances, greenhouse gases, energy or water.

Applying for a Recognition Award

Organizations that would like to be considered for a P2 Recognition Award should complete the online application during the open nomination period. P2 efforts must have taken place within the past three years. The 2025 application period will likely open early Spring 2025.

The type of information requested on the application questionnaire includes a description of the organization, the P2 practice or project implemented, and the measurable results from the P2 action. The application also provides the opportunity to describe the organization’s commitment and leadership in P2, how the P2 efforts benefited the organization and affected communities, and the organization's future P2 goals.

Scoring: Point values for each question are listed in the application questionnaire. Award recipients will be selected based on their responses to the application questions. Each response has a character limit. Applicants may include relevant photographs, news articles, or other media for consideration. EPA reserves the right to contact the applicant to clarify any questions regarding the application.

For additional information or questions, please contact:Margaret Reynolds

EPA Region 4 Pollution Prevention Project Coordinator

reynolds.margaret@epa.gov

This collection of information is approved by OMB under the Paperwork Reduction Act, 44 U.S.C. 3501 et seq. (OMB Control No. 2008-0004). Responses to this collection of information are voluntary 85 FR 35652. An agency may not conduct or sponsor, and a person is not required to respond to, a collection of information unless it displays a currently valid OMB control number. The public reporting and recordkeeping burden for this collection of information is estimated to be 19.5 hours per response. Send comments on the Agency’s need for this information, the accuracy of the provided burden estimates and any suggested methods for minimizing respondent burden to the Regulatory Support Division Director, U.S. Environmental Protection Agency (2821T), 1200 Pennsylvania Ave., NW, Washington, D.C. 20460. Include the OMB control number in any correspondence. Do not send the completed form to this address.

2024 Region 4 Pollution Prevention Recognition Award Winners

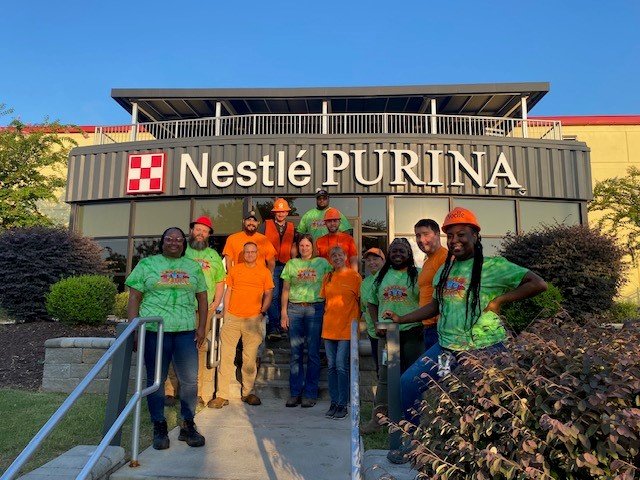

Nestle Purina Petcare Company | Hartwell, GA

Nestle Purina Petcare Company manufactures wet dog and cat food and operates a distribution center. They are currently a zero waste for disposal facility and utilize composting, waste to energy, recycling, and reuse to obtain zero waste for disposal status. In 2022, Nestle Purina Petcare’s Hartwell Factory underwent a water and energy reduction workshop that illuminated several opportunities for P2 improvements. Projects included a water balance study to optimize the retort/reclaim system, closing off waterlines that no longer were in use, and a 20psi reduction in operation pressure in the high-pressure hot water system. All of these changes contributed to significant reduction in water and energy usage. In addition to these projects, the Hartwell Factory also installed a collection system in the boiler room that returns the condensate to the boiler deaerator and implemented operational changes to save water, energy, and costs. In 2022-2023, the culmination of these projects resulted in reduced water usage by 66 million gallons, reduced energy usage by 2 million kWh, and realized cost savings of approximately $760,000.

Evonik Corporation, Mobile Facility: Theodore, AL

The implementation of new digital tools at Evonik Corporation's Mobile, Ala., site has led to an estimated reduction of the company's environmental footprint by over 3 million kilowatt hours, 9 million gallons of freshwater, and 2,400 metric tons of carbon dioxide per year. A manufacturer of specialty chemicals for a variety of products and applications, Evonik goes far beyond chemistry to create innovative, profitable, and sustainable solutions for customers.

In 2021, Evonik’s Mobile site implemented an Advanced Process Control (APC) project which optimized the energy efficiency of six chillers that varied in age and efficiency. The new APC controller can factor in the different water temperatures, respond more quickly to changes in demand, and optimize the flow of cooling water to the chillers, resulting in a more efficient, cost-effective, and sustainable system.

2023 Region 4 Pollution Prevention Recognition Award Winners

Consolidated Nuclear Security, LLC. (CNS): Y-12 National Security Complex | Oak Ridge, TN

Operated by CNS (Consolidated Nuclear Security, LLC), the Y-12 National Security Complex is a manufacturing facility dedicated to ensuring a safe and effective United States nuclear weapons deterrent.

In 2020, the Utilities Department at the Y‐12 National Security Complex used 17,120 gallons of a bio‐based transformer fluid to retro-fill 20 transformers, while being able to recycle 19,673 gallons of transformer fluid from this activity. The purpose of the project was to conserve natural resources, reduce costs to Y‐12, support pollution prevention/sustainable acquisition initiatives, and comply with federal regulations. This transformer fluid has a lower flammability rating than previously used transformer fluids and produces 56 times less carbon dioxide emissions than mineral oil.

2021 Region 4 Pollution Prevention Recognition Award Winners

Siemens Energy Inc | Richland, MS

Siemens Energy is a manufacturer of high voltage circuit breakers and voltage regulators for the power transmission industry.

Motivated to reduce energy consumption internally, in 2019 Siemens Energy completed a multi-factor project that improved process efficiency and reduced electricity use. Siemens Energy identified two areas within the climate-controlled facility that were losing conditioned air each time equipment entered or exited the building. The facility replaced the traditional roll up doors with high-speed doors, reducing energy consumption by over 60,000 kWh. The company also identified and implemented opportunities of automation and air flow improvements related to compressed air systems, realizing an energy reduction of over 200,000kWh. The energy reduction project resulted in over 260,000 kWh of annual electricity savings and 239,000 pounds of annual CO2 equivalent avoidance.

Siemens Energy is actively involved in state-led P2 projects through the Mississippi Department of Environmental Quality as well as employee-led environmental initiatives to promote recycling and waste reduction. Siemens Energy’s participation in the MDEQ enHance program has challenged them to focus on internal practices and product design to reduce waste at the source.

Shutterfly, LLC |Fort Mill, SC

The Shutterfly family of brands together make up an online retail and manufacturing platform for photography and personalized products.

In 2021, Shutterfly changed their process and workflow configuration for card production to decrease waste and materials used. All of the Shutterfly manufacturing facilities increased product batch sizes run by the digital printing presses across each manufacturing facility. This improvement helped Shutterfly achieve their sustainability goals for year-over-year waste reduction and reducing costs by eliminating the use of 267,000 sheets of large-format paper. This is roughly the equivalent of 100 trees. Shutterfly plans to expand this process change to a greater number of products in 2022, further reducing waste produced during the printing process. In 2021, Shutterfly also replaced many of their older presses with newer models that reduce energy usage and VOCs emitted. In 2019, the header sheets were redesigned to reduce ink coverage by 60% per sheet, demonstrating that this approach to production is a key part of the business.

Shutterfly’s P2 activities have contributed to a 24% decrease in waste produced, 7% decrease in energy usage, and reduced impact on natural wood resources through saving thousands of B2-size sheets of paper.

Ford Motor Company | Louisville, KY Assembly Plant

Ford designs, manufactures, markets and services a full line of connected, increasingly electrified passenger and commercial vehicles.

In 2020, Ford began implementing a pollution prevention project to reuse treated wastewater treatment (WWT) effluent in the paint pretreatment process. The goal was to reduce the volume of water sent to the Publicly Owned Treatment Works (POTW) and reduce the amount of freshwater being used in the manufacturing process. First, the pre-treated WWT effluent is filtered with an ultrafiltration system to further remove suspended solids and total organic carbon. Then, the effluent is further clarified by a reverse osmosis system producing a high quality permeate that is used in the paint pretreatment process.

During the first year of project implementation, the facility reduced over five million gallons of city water, which equates to over 22 gallons/vehicle. This equates to a savings of approximately $50K. The full potential of the system is expected to further increase as production stabilizes from the effects of the COVID-19 pandemic.